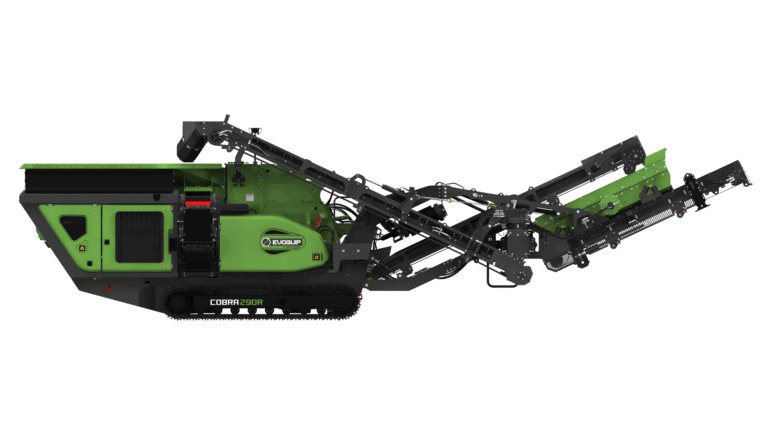

Cobra 290R Impact Crusher

The Cobra 290R is a versatile and easy to use Track Mounted Impact Crusher that can operate in the most demanding of applications such as Reinforced Concrete, Recycled Asphalt, Construction and Demolition waste and Natural Rock. The integrated Afterscreen system on the Cobra 290R ensures the required product specification is achieved with oversize material either being recirculated back to the Crusher or else stockpiled.

At the heart of the Cobra 290R is the Terex Impact Crusher with a rotor size of 1000mm (40″) x 1034mm (41.5″). This impactor has been developed using components and technology from some of the company’s larger impactors within the Terex range.

Fitted as standard is a hinged inlet lid, which greatly reduces the risk of material bridging at the feed in point. Like the Cobra 230 crusher, the Cobra 290R also has two independent hydraulic controlled aprons, which allow the operator to optimise the material throughput and reduction.

The patented hydraulic overload protection system used not only protects the crusher in the event of an uncrushable piece entering the chamber but it also minimises apron bounce and reduces the amount of oversize material passing.

The Cobra 290R is available with the wind sifter as an option, providing the ideal solution to remove contaminants such as plastic and wood from crushed C&D waste based on density and size.

DEMO DAY - Come and see this Shredder Live in Action

Showcasing the TBG High Speed Shredder. Learn more about its features, benefits, and see it process bark and wood products live in action.

Lunch and refreshments provided.

Date: Friday 26th April, 2024

Time: 12pm midday

Location: Taupo Bark Products, 2/131 Centennial Drive, Taupo

RSVP to Dan Meikle dan@mobilescreening.co.nz | 0272 255 838

Enquiry

Key Features

-

- Perfect solution for on-site recycling in urban areas

- Fuel-efficient and high-performing direct drive system

- Easily transported from job to job

- Ready to crush in minutes as a result of ground level set-up

- Intuitive two-button start-up sequence

- Versatile and easy to use and can operate in the most demanding of applications

- Two independent hydraulic controlled aprons which allow the operator to optimize the material throughput and reduction.

- The patented hydraulic overload protection system protects the crusher in the event of an uncrushable piece entering the chamber and minimizes apron bounce.

- Oversize material either being recirculated back to the crusher or stockpiled.

Technical Specifications

____________

Hopper

Hopper capacity – 3.3m3

Output

Up to 290 tph

Crusher

Crusher inlet – 1030mm x 790mm

Chamber also features a hinged inlet lid which greatly reduces the risk of material bridging at the feed in point

Pre-screen

2.74m x 1.5m post screen

Integrated pre-screen which can be configured to suit multiple applications

Afterscreen

Aggressive 9’ x 5’ single deck screen

Conveyor

Conveyor – 1m (W)

Powerunit

315Hp engine

Feeder

Vibrating feeder