Stock

Machinery in STOCK now

We have a variety of new and used / ex-rental equipment available for purchase now, with more on the way. Dont see what you are looking for? Contact either Dan or Stew to discuss your requirements.

LANDED IN NZ

EVOQUIP COBRA 290R IMPACT CRUSHER (NEW)

The Cobra 290R rock crusher is a versatile and easy to use Mobile Impact Crusher that can operate in the most demanding of applications such as Reinforced Concrete, Recycled Asphalt, Construction and Demolition waste and Natural Rock.

- Ready to crush in minutes as a result of ground level set-up

- 34m x 1.17m (8’ x 4’) Double deck screen

- Hopper capacity – 3.3m3

- Crusher inlet – 1030mm x 790mm

- Afterscreen – Aggressive 9’ x 5’ single deck screen

- Up to 290 tph

- Oversize material either being recirculated back to the crusher or stockpiled.

- Intuitive two-button start-up sequence

- Fuel-efficient and high-performing direct drive system

EVOQUIP COBRA 230R IMPACT CRUSHER (NEW)

The Cobra 230R rock crusher is a versatile and easy to use Mobile Impact Crusher that can operate in the most demanding of applications such as Reinforced Concrete, Recycled Asphalt, Construction and Demolition waste and Natural Rock - with integrated after screen system.

- Crusher inlet – 860mm x 720mm

- 830mm x 860mm (33″ x 34) diameter rotor

- Conveyor – 900mm (W)

- 2 High / 2 Low configuration as standard

- Output potential – up to 250 tph

- Hopper capacity – 2.6m3

- Min CSS: 40mm (1.5″) upper; 20mm (0.75″) lower

- Max OSS: 120mm (4.75″) upper; 55mm (2.25″) lower

- Hydraulic adjust and hydraulic overload protection as standard

- Integrated pre-screen for fines removal

- Feeder speed auto-regulates depending on crusher load

- 2.44m x 1.2m (8′ x 4′) single deck

- Afterscreen system is quick to detach

- Intuitive ‘Push Button’ control system

EVOQUIP COLT 1600

SCALPER SCREEN

(NEW)

The high capacity, versatile heavy-duty Colt 1600 Screener Machine is designed to work in primary and secondary screening applications

- High-capacity incline apron feeder as standard

- 7m³ standard hopper capacity

- 4.8m x 1.53m (16′ x 5′) double deck screen

- Up to 600 TPH

- Configurable layout

- Variable screening angle

- Operates in both heavy-duty scalping and precision screening

- Wide array of screen media available

- 1200mm (48″) wide collection conveyor

- Variable speed on fines, midgrade and oversize as standard

TDS820 LOW SPEED SHREDDER (NEW)

The TDS 820 is an aggressive Slow Speed Shredder purpose-built to process all types of material, whether it be domestic, industrial or bulky waste.

- Hydrostatic drive; providing increased protection against contamination and allowing bi-directional shredding

- The double shaft shredder has 2m long shafts with a fully welded tooth configuration, impressive throughput and excellent reduction.

- The independent gearboxes enable each shaft to be run separately helping to reduce wrappage and improve the shredding of material.

- Fully customisable programming of shafts to increase production, fine tune product and minimise fuel consumption.

- Additional features include the tipping feeder which increases the feed area. Hopper extensions provide increased capacity in bulky applications.

- A powerful Scania engine with a low operating speed combined with an efficient hydrostatic drive creates a very responsive shredding action with protection against un-shreddable contaminants.

TBG530 HIGH SPEED SHREDDER (NEW)

The TBG 530T is a robust, track mounted high speed shredder ideal for medium scale producers requiring an accurate and consistent end product. Extremely versatile, it excels in many applications and is particularly suited to waste wood processing and green waste shredding.

- Unrestricted full width feed hopper

- Product conveyor discharge height – 4.6m

- Lowers to ground level for maintenance access

- Direct drive rotor for efficient shredding

- Single piece solid or replaceable tip hammer Options

- Optional High strength overband magnet w/ hydraulic height adjustment

- Intelligent feed wheel with lift and downward assist

- Variable infeed speed intelligently linked to engine load and/or engine RPM

- Removable bypass plate to allow fines material to bypass rotor

TC65 STACKER (NEW)

The Evoquip TC65 Stacker features a conveyor length of 65ft (20m) and a capacity of up to 500 tph.

- Conveyor Length: 19.79m

- Belt Width: 1050mm (42″)

- Conveyor Drive: Hydraulic 800cc

- Discharge Height: 9.1m @ 24°

- Max Discharge Height : 9.45m @ 28°

- Hydraulic Folding Head Section

- Hydraulic oil cooler as standard

- Belt Scales

- Up to 500 tph.

ON THE WAY

COLT 600 SCALPER SCREEN (NEW)

The Evoquip Colt 600 is a compact and aggressive forward-facing screen that can work in aggregates, sand and gravel, top soil, construction demolition and recycling applications where site space is at a premium

- (8’ x 4’) Double deck screen

- 3m3 (3.9yd3) Hopper capacity

- Ability to convert to 2 way split

- Feeder: 1m Wide

- 650mm Wide fines conveyor / 2.9m discharge

- 650mm Wide midgrade conveyor / 2.8m discharge

- 1000mm Wide oversize conveyor / 2.7m discharge

- Variable speed on midgrade and oversize as standard

- Rapid conversion from three-way split to two-way split

- High-capacity up to 280tph

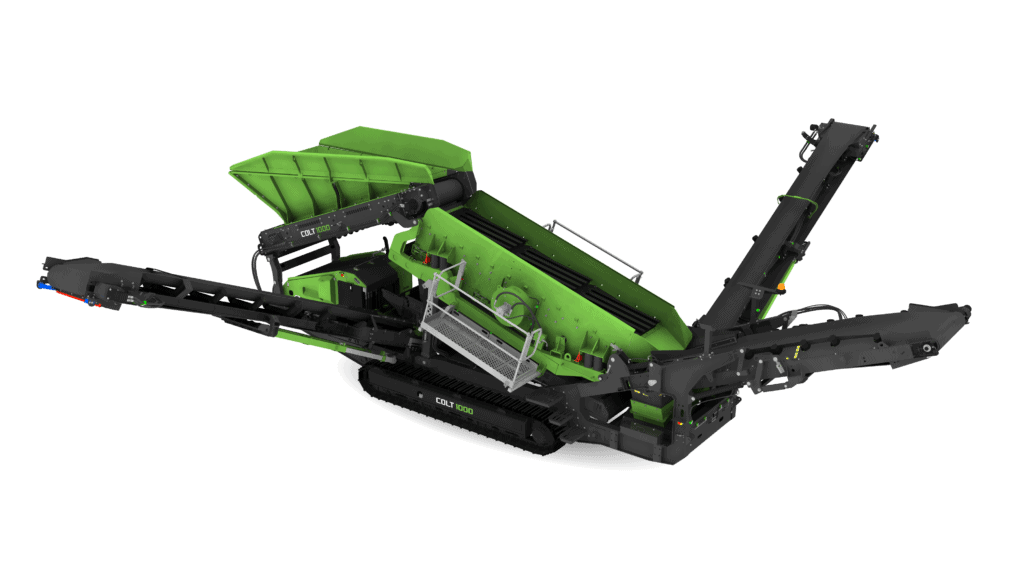

COLT 1000 SCALPER SCREEN (NEW)

The highly adaptable Evoquip Colt 1000 Scalping screen is able to operate in both heavy duty scalping and precision screening applications and will manage the most difficult of materials. Flexibility is enhanced with configurable conveyor and two way split option. Featuring an aggressive double deck screen, variable screening angle with numerous screen media options, broad fines conveyor, quick set up time and tall discharge heights.

- 5m³ standard hopper capacity

- 4.1m (13’6”) x 1.22m (4’) Double deck screen

- Configurable layout and ability to convert to 2 way split

- Variable speed on feeder, fines, mid-grade and oversize as standard

- Up to 360TPH (Depending on Application)

- Simple, intuitive control system operation

- Wide range of screen media

- Top Deck – Bofor Deck, Fingers, Punch Plate, 3D Punch Plate & Mesh

- Bottom Deck – Mesh & Fingers

LLOYD ENGINEERING SCREENING BUCKETS (NEW)

The Lloyd Engineering range of Star screening buckets come in different size models to fit most Excavators. The star bucket has a unique screening action that rotates the material in a similar manner to a rotary / trommel bucket but has the benefit of rotating star discs agitating and clawing at the material as it turns. This is achieved by mounting star shafts on a large arc forming the back and top of the bucket.

- Various models IN STOCK NOW

- RS20-30 (largest model) processes up to 90TPH @ 18mm aperture!

- Models to suit a wide range of Excavators

- Massive screening area

- Durable self-cleaning stars

- Carrier weight: 3-to-30-ton excavators

- Flexible, Self-Cleaning, Easily Replaceable Polyurethane Stars

- Uncompromised Quality with High-Output

- The shafts operate in one direction only and require a standard one-way hammer circuit. This also eliminates the need for a drain line.

PRICE: $13K - 45K + GST

POA: Price is dependent on rate of exchange at time of quotation.

TBG 530 HIGH SPEED SHREDDER (NEW)

The TBG 530T is a robust, track mounted high speed shredder ideal for medium scale producers requiring an accurate and consistent end product. Extremely versatile, it excels in many applications and is particularly suited to waste wood processing and green waste shredding.

- Unrestricted full width feed hopper

- Product conveyor discharge height – 4.6m

- Lowers to ground level for maintenance access

- Direct drive rotor for efficient shredding

- Single piece solid or replaceable tip hammer Options

- Optional High strength overband magnet w/ hydraulic height adjustment

- Intelligent feed wheel with lift and downward assist

- Variable infeed speed intelligently linked to engine load and/or engine RPM

- Removable bypass plate to allow fines material to bypass rotor

CAIMAN 150 SHREDDER (NEW)

The Caiman 150 provides high output with low operational costs and canbe used in multiple applications such as C&D, asphalt, skip waste, green

waste, wood, household waste and mattresses.

Its compact and robust design allows it to be used in the smallest of spaces whilst maintaining an aggressive and powerful shredding system. With an intuitive control system, the Caiman 150 is user friendly, and its compact

transport envelope allows it to be transported easily between sites.

- Versatile design for multiple applications

- Twin slow speed high torque shafts

- Intuitive Control System

- Default and Customisable

shredding programs - Quick removal of shafts/combs

- Asynchronous shredding action

- Compact robust design

- Hydrostatic drive

- Double shaft shredder

- Easy Service Access